- Designed & manufactured for painting motorcycle plastic part

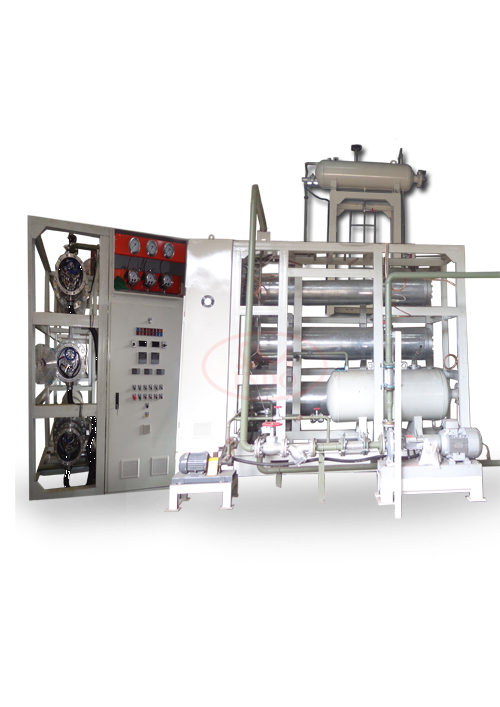

- Continuous production type

- Work piece moving system by overhead trolley conveyor

- 6 section flow process (Loading, wiping, painting, settling, baking & unloading)

- 2 Section painting layer (Under coat & Top coat)

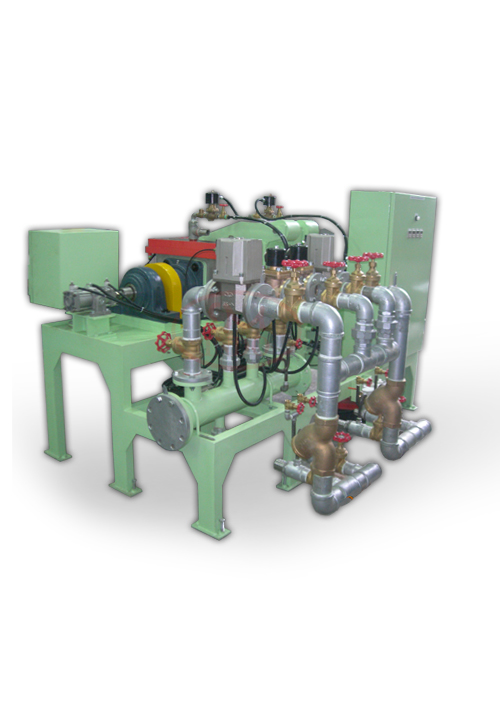

- Water curtain ventury painting booth system with:

- SUS 304 Stainless Steel construction material

- End ducting centrifugal water pump

- Exhausted air by U-Belt drive axial fan

- Filtered intake air supplied by centrifugal blower

- 1 section settling room constructed by mild steel material

- 1 section baking oven with :

- Galvanized steel construction material

- Radiant heating by infrared silica quartz heater

- Operating temperature : 70°C

- 3 zones heating control

- Full proportional heating control by SCR power regulator

- Remote floor standing type electrical control panel

- Microprocessor based digital indicating temperature controller on each zones

- Safety operation system (Full interlock wired between conveyor, painting booth & baking oven)

- Easy to see incoming voltage, running current, conveyor speed, chamber temperature of baking oven, indicating lamp of paint booth pump, exhaust fan, intake blower & intake filter condition.

Spare Parts Warranty : 1 Year (Normal Operation)

.jpg)