- Office (+62) 21 556 62 440 |

- cs@smindo.co.id

by Cuthbert Liaw | Wed, 10 September 2025

Key Differences Between Ashing Furnaces and Muffle Furnaces

Understanding the distinctions between an ashing furnace and a general-use muffle furnace is crucial for laboratories and industries that rely on precise thermal processing. An ashing furnace is purpose-built to promote pre-heated air, aiding in oxidizing and decomposing organic materials in the presence of oxygen, leaving only inorganic ash residues for analysis. This specialized equipment ensures complete combustion of volatiles by controlling both temperature and airflow within the chamber.

A muffle furnace, by contrast, does not promote combustion, with refractory semi-isolating test samples from direct contact with significant amount of air (not vacuum or inert atmosphere).

The Ashing Process: What It Is and When It’s Used

The ashing process involves heating a prepared sample in an oxygen-promoted environment to oxidize and volatilize organic matter, leaving behind only inorganic residues for weighing or further analysis.

Common use cases include:

SUHATHERM Ashing Furnace ASF-05/5

PT Suhatherm manufactures high-quality ashing furnace, ASF-05/5, with 5 ltr capacity and integrated airflow tunnel technology, and temperatures up to 1200 °C.

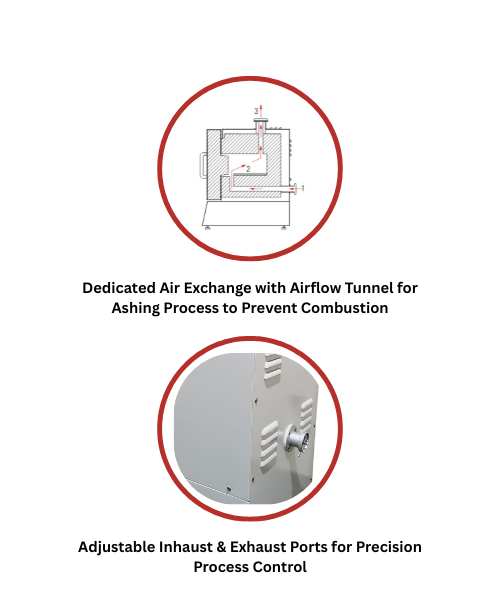

Suhatherm’s ashing furnace integrates an airflow tunnel technology engineered to introduce air and promote ashing process.

ASF-05/5 ashing furnace key features include:

For detailed specifications of SUHATHERM ASF-05/5 ashing furnace, contact PT Suhatherm Manufacturing Indonesia today at cs@smindo.co.id, and visit our website at www.smindo.co.id